The Critical Role of Optical Fibre Diameter Analyser in High-Speed Internet Infrastructure

The Critical Role of Optical Fibre Diameter Analyser in High-Speed Internet Infrastructure

Blog Article

Exactly How an Optical Fibre Diameter Analyser Enhances Top Quality Control in Fibre Manufacturing

The combination of an Optical Fibre Diameter Analyser into Fibre production procedures represents a significant innovation in quality assurance methodologies. By supplying real-time, accurate dimensions of Fibre diameters, this technology attends to the important demand for consistency in production requirements. With its capacity to quickly identify variances and prompt restorative measures, the analyser not just enhances product integrity but additionally contributes to general functional effectiveness. As sectors increasingly focus on top quality and compliance, recognizing the full effect of such technologies becomes necessary. What implications could this have for the future of Fibre manufacturing?

Relevance of Fibre Diameter Dimension

Exact dimension of Fibre Diameter is important in the field of optical Fibre technology, as it directly affects the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre affects its light-carrying capacity, depletion, and total transmission performance. Accuracy in determining Fibre Diameter makes certain that the optical properties are kept within defined resistances, which is important for optimal signal honesty.

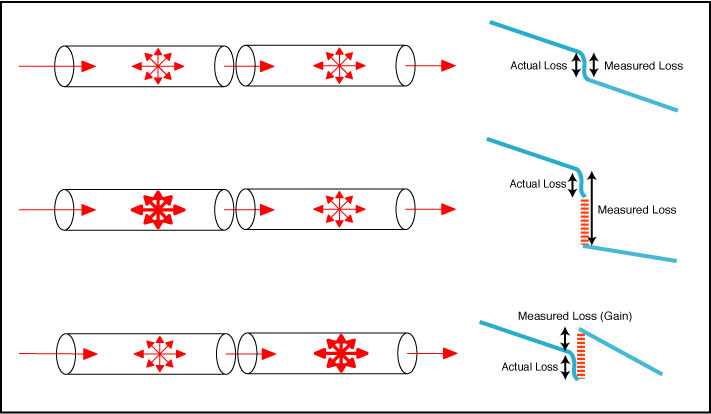

Variants in Fibre Diameter can bring about raised losses because of scattering and modal dispersion, influencing the high quality of data transmission. In high-speed communication systems, such disparities can lead to significant degradation of signal high quality, bring about information errors and reduced efficiency. Moreover, regular Fibre Diameter is crucial for compatibility with ports and splicing technologies, which are indispensable parts of Fibre optic networks.

Quality assurance processes in Fibre production greatly rely upon exact Diameter dimensions to ensure conformity with industry requirements. By implementing durable measurement methods, manufacturers can improve item dependability, decrease waste, and enhance total system performance. Therefore, the importance of Fibre Diameter dimension can not be overstated, as it offers as a cornerstone in the improvement of optical Fibre technology and its applications in contemporary interaction networks.

How the Analyser Functions

The reliable measurement of Fibre Diameter counts on advanced analytical techniques that make sure precision and reliability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a mix of laser technology and progressed photo processing algorithms to precisely analyze the Diameter of fibres as they are produced

At first, a laser light beam is directed at the moving Fibre, producing a cross-sectional darkness. The analyser records this darkness making use of high-resolution video cameras positioned tactically along the assembly line. The recorded images are then processed in real-time to identify the Fibre's Diameter with outstanding precision.

The system makes use of innovative algorithms that account for various elements, including variations in light intensity and environmental conditions, to enhance measurement dependability. It can find minute adjustments in Diameter, such as changes that may happen throughout the manufacturing process.

In addition, the analyser can taking care of several fibres at the same time, enhancing throughput without compromising precision. By supplying instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays a crucial duty in keeping strict quality control criteria, making certain that the last product fulfills market specifications and consumer demands.

Benefits of Real-Time Surveillance

While standard methods of checking Fibre Diameter commonly involve taxing post-production checks, real-time tracking significantly boosts the efficiency and top quality of optical Fibre production. optical fibre diameter analyser. This positive strategy enables manufacturers to determine deviations in Fibre Diameter as they occur, rather than waiting till manufacturing is complete to analyze high quality

By continually measuring the Diameter during production, suppliers can guarantee that the fibers meet rigid specifications, resulting in lowered variability and enhanced uniformity. Real-time monitoring additionally enables instant rehabilitative activities to be taken, reducing waste and protecting against defective fibres from going into the supply chain.

In addition, this technology assists in boosted Get More Info data collection and analysis, supplying understandings right into production trends and prospective locations for renovation. Such data-driven decision-making empowers producers to enhance procedures and keep high criteria of quality control.

Furthermore, real-time tracking promotes a society of continual renovation within the manufacturing environment. Employees are more engaged when they can see the effect of their operate in real-time, resulting in increased responsibility and a dedication to excellence. On the whole, the execution of real-time surveillance systems in optical Fibre production converts to premium item top quality and raised consumer satisfaction.

Effect On Production Performance

Implementing optical Fibre Diameter analysers substantially improves production effectiveness by improving the manufacturing procedure. These tools promote continual tracking of Fibre Diameter, permitting makers to find variances in real-time. By determining disparities promptly, assembly line can be readjusted swiftly, reducing downtime and reducing the chance of creating faulty products.

In addition, the combination of these analysers into the manufacturing process enables far better resource allocation. With exact Diameter dimensions, operators can maximize material use, making sure that resources are not thrown away on problematic fibers. This accuracy also official site adds to less remodel and scrap, inevitably reducing manufacturing costs.

The automation given by optical Fibre Diameter analysers reduces dependence on manual assessments, which are frequently taxing and prone to human error. Consequently, staff members can focus on even more strategic tasks, boosting overall efficiency.

Moreover, the data created from these analysers can inform process enhancements and promote better decision-making. By examining trends in Fibre Diameter variants, suppliers can implement positive actions to enhance production methods and keep regular quality. In summary, optical Fibre Diameter analysers play an essential role in increasing manufacturing performance, leading to higher high quality outcome and boosted success.

Study and Success Stories

Throughout numerous sectors, study highlight the transformative effect of optical Fibre Diameter analysers on production processes. One famous instance is a leading telecoms business that dealt with obstacles with irregular Fibre sizes, causing boosted denial prices. By incorporating an optical Fibre Diameter analyser, the business achieved real-time monitoring of Fibre dimensions, causing a 30% decrease in issues and substantial price financial savings.

Furthermore, a study establishment concentrating on advanced products utilized optical Fibre Diameter analysers to fine-tune their speculative processes. The analyser's capacity to supply detailed understandings into Fibre uniformity enabled the growth of innovative products with better performance features.

These success stories highlight the important function of optical Fibre Diameter analysers in improving quality assurance, enhancing manufacturing efficiency, and driving development throughout diverse markets.

Verdict

In final thought, the Optical Fibre Diameter Analyser plays a critical role in enhancing quality control within Fibre manufacturing. As shown via numerous situation research studies, the analyser verifies vital for accomplishing remarkable product quality in Fibre check over here production.

The implementation of optical Fibre Diameter analysers enabled for rigorous high quality control, making certain that the created fibers satisfied exacting sector standards.In final thought, the Optical Fibre Diameter Analyser plays an essential role in improving high quality control within Fibre manufacturing.

Report this page